VMC-4000S

VMC-4000S

Origin:Taiwan

Model:VMC-4000S

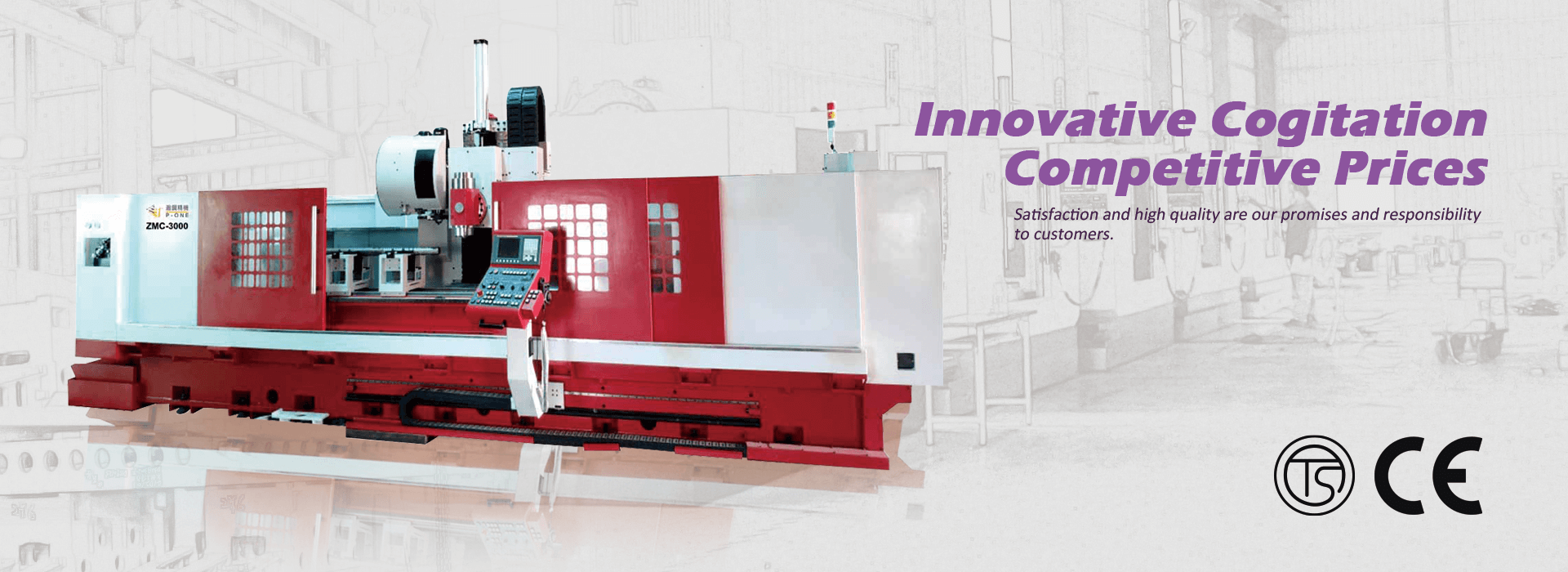

※ It’s suitable for heavy-duty machining such as long strip-shaped, pallet, steel, iron, casting etc.

※ It’s applicable to complex processing needs- milling, cutting and drilling.

※ For the demand of the precision heavy machinery equipment, transportation equipment and power equipment etc machining.

※ Advantages:

(1) High rigidity structure equipped with heavy load linear slide to share the load evenly. Lower wear rate, lower lost motion and deformation resistance.

(2) The machine is running smoothly and provides better surface finish with high accuracy for long-term operation.

(3) The moving column mechanism is a great substitute for double column type machining center is due to space-saving.

|

VMC-4000S |

|

|

X-axis Travel |

4000mm (Random length_Opt.) |

|

Y-axis Travel |

450mm / *560mm(Opt.) |

|

Z-axis Travel |

500mm |

|

Spindle nose to table |

90~590mm |

|

Spindle center to column |

650mm |

|

SPINDLE |

|

|

Spindle Speed |

8000rpm |

|

Spindle Taper |

BT- 40 |

|

FEEDRATE |

|

|

Rapid Traverse(X) |

12m/min |

|

Rapid Traverse(Y,Z) |

15m/min |

|

Feed Rate(X,Y,Z) |

1- 6000mm/min |

|

AUTO TOOL CHANGER |

|

|

Magazine Capacity |

24 |

|

Tool Change Type |

Arm type |

|

Max. tool change diameter |

ø75mm |

|

Max. tool weight |

7kg |

|

MOTOR |

|

|

Spindle Motor(cont/30min) |

AC 11/15kw |

|

Axise Servo motor |

Mitsubishi 3.0kw |

|

Machine Dimension(LxWxH) |

8590*3700*3100mm |

|

Machine N.W. |

17500kg |

| Item |

Standard accessories |

Optional accessories |

| 1 |

3 axes telescopic cover |

Coolant thru spindle(CTS) |

| 2 |

Full-enclosed splash guard |

Transformer |

| 3 |

3 axes oil lubrication system with press-relief circuit |

Buzzer |

| 4 |

Screw type chip conveyor |

Air conditioner for electric cabinet |

| 5 |

Coolant system |

4th Roatry table & device(com. set) |

| 6 |

Pneumatic fitting for 3-point built up |

4th axis preparation(servo, wiring only) |

| 7 |

Spindle air blast |

Spindle oil cooler |

| 8 |

Square type protective tube |

Wash down device |

| 9 | Adjustment tools and toolbox | Oil skimmer |

| 10 | Heat exchanger for electric cabinet |

Optical scale for 3 axes |

| 11 | Leveling pads and bolts | Tool setting probe |

| 12 | Working light |

Work piece measuring probe |

| 13 | M30 auto power off | Scraper type chip conveyor + bucket |

| 14 | RS232/USB/CF interface |

Oil mist collector |

| 15 | Warning light |